|

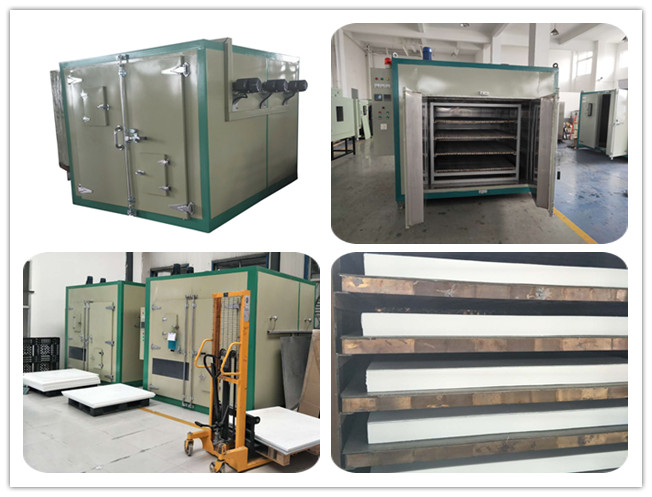

PTFE molding sheet sintered oven with less tolerance for sintereing temperature around ±3°C, and keep inside heating is uniform. Use stainless steel material for make it. Suit for PTFE molding sheet sintered. As requirements can design different size.

Working measurement:1500(D)×1500(W)×1500(H)mm

Temperature range: RT10 ~ +450℃

Temperature uniformity:≤±3℃

Temperature fluctuation:±1℃

Heating power: 30KW

Heating zone: 4 zones

Fan motor: 0.75kwX4 piece

Setting any range temperature acceptable

- Use full unit structures

- Inside use 1.2mm SS304 stainless steel panel, outside shell use 1.5mm stainless steel sheet welding together,outside print CPI of Logo, inside and outside connect place adopt heating treatment(means less heater go outside), And use a laser cutter to cut the cross seam, to reduce thermal conductivity as much as possible,and inside and outside use ceramic fiber bags for separated. Electricity parts in the left side. Inside will put one shaft,total 4 layers, one layer can bear 500KG, each tray use 50*50*2.5 carbon steel welding it, and each tray in the up use stainless steel panel, and make Ø14 holes, stainless steel make sure surface is smooth and no bur.

- Inside oven keep heating material is use high-density high-quality aluminum silicate cotton, heating material Heat transfer coefficient ≤0.04, and the door use 2 layer ceramic fiber rope, inside all fastener use stainless steel material, and with double door for open. And use hand for open the door, also in the door with one window for checking.

- In the unit two side setting one air adjust cabinet, and this place install seamless stainless steel heating tube, fan motor etc device, each heating tube use separate circuit breaker control it, can adjust heating power according to product quantity.

- Temperature sensor is placed at the air(wind) outlet

- Air (Wind) working route: horizontal wind out, suction on both sides of the cabinet

|